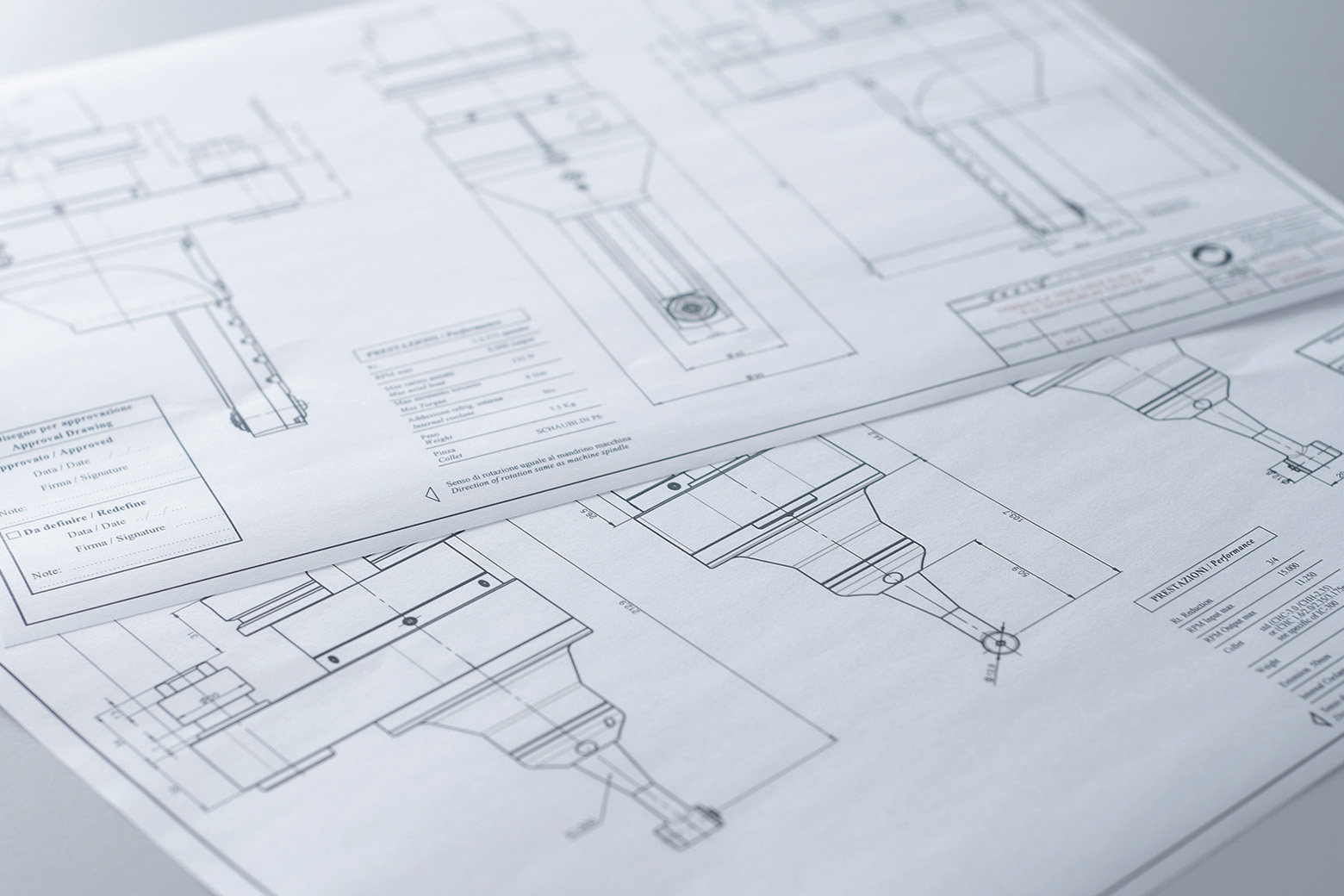

A customised angle head is no longer a standard one!

Care for detail, passion, and attention to design: Alberti products are the result of continuous improvement.

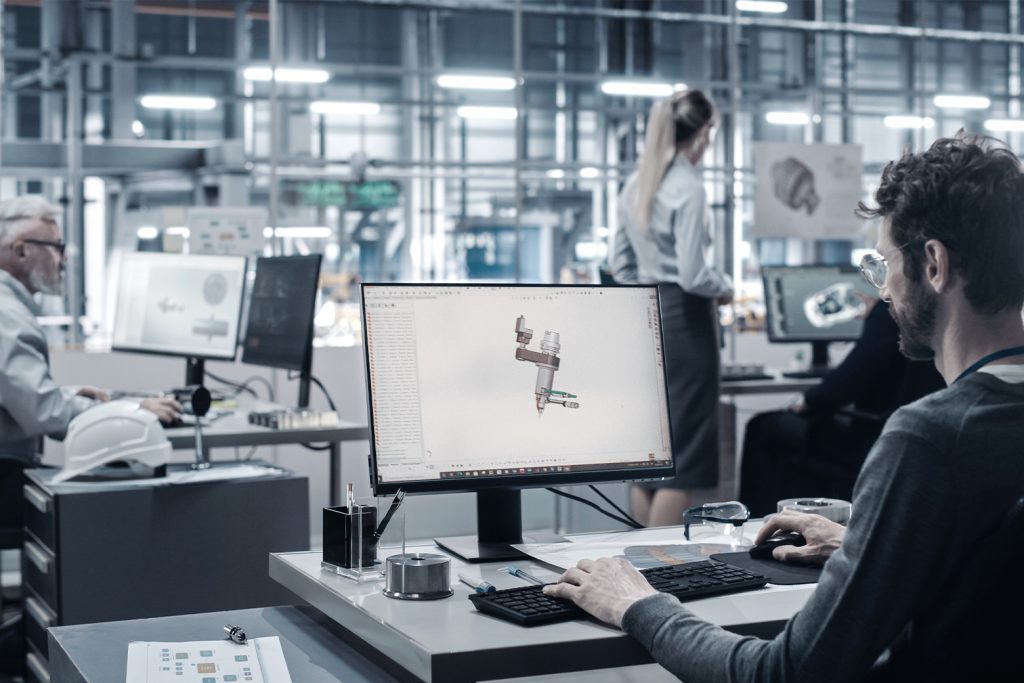

The R&D team works to achieve: the constant improvement of the existing lines to offer an increasing range of configurable options of the standard line and the development of test products born from the most special needs of certain customers and which foresee an interesting evolution for our field.

We are constantly improving our products, exploiting the latest technologies, and studying material tightness and processing time optimization.