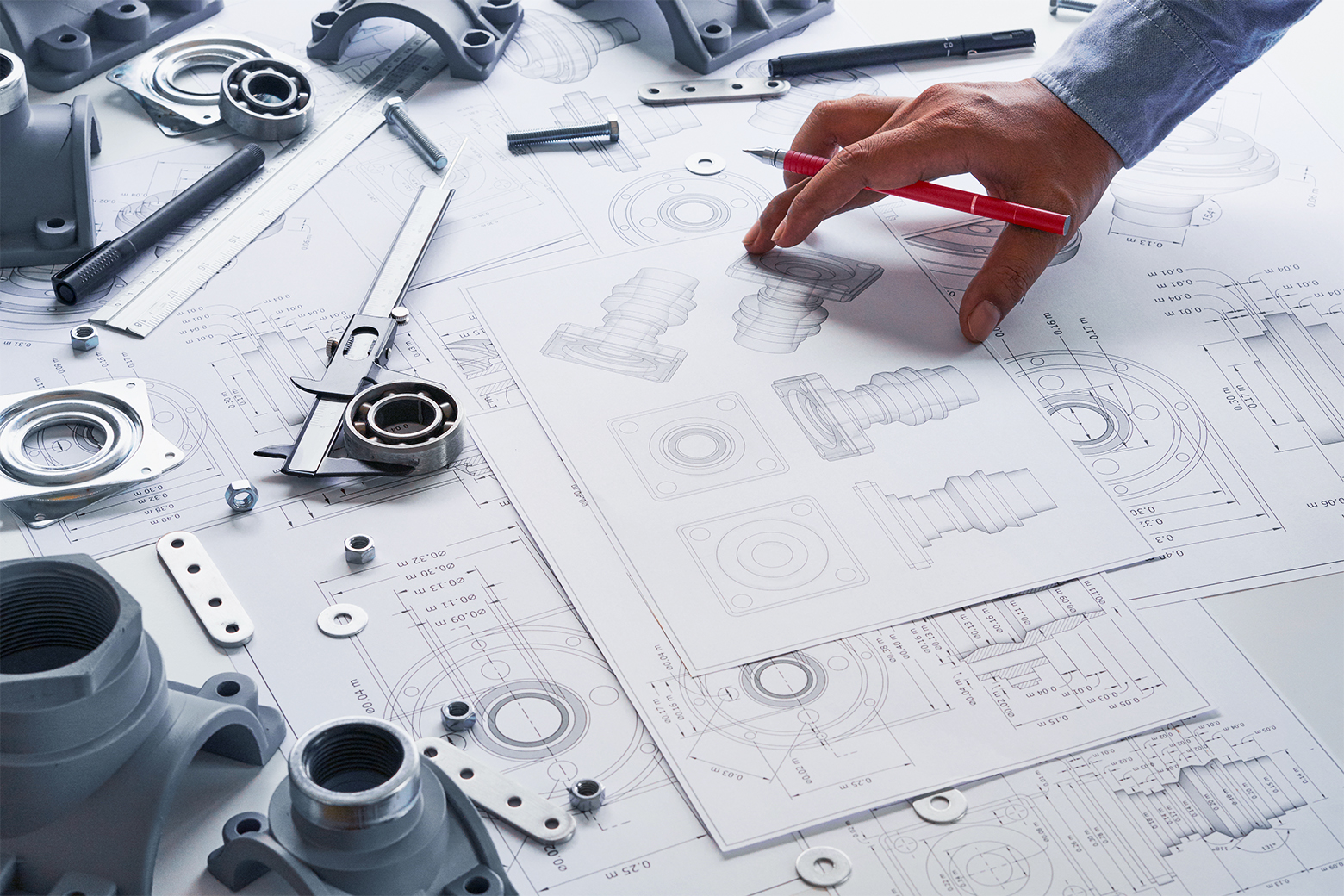

This is where Alberti angle heads are designed and manufactured.

Alberti Umberto S.r.l. is an innovative company: the headquarters are on three floors with highly energy-efficient materials. 4000 square meters, dedicated to state-of-the-art technology: open-space offices, a large and elegant meeting room, an exhibition showroom and, above all, a large production department including a wide range of machines, such as milling, turning and grinding centers; a three-dimensional measuring machine and an assembly department.

In addition, a big logistics department and a spare parts warehouse to meet the needs of over 60,000 products delivered worldwide.

Alberti Umberto S.r.l. is easily accessible from the motorway: it is strategically located halfway between Milan, Varese, and Como – I – in Via Gorizia 37 – Saronno (Varese).